High quality mechanism made in Italy

It’s been

40 years that the firm Renato Nisi treats with precision and attention all

production stages of the product to the sale, assisting with the utmost

professionalism and reliability the demands of its customers. The raw

material purchased is equipped with all international certifications and, in

our structures, is transformed through processes constantly subjected to

quality control. Therefore, the manufactured items will be innovative and

completely Made in Italy.

Cut: The latest generation of numerical control cutting machines, ensuring a pinpoint accuracy in the process.

Printing: Mechanical presses use for each components some special molds called "pace", fed by unwinding at numerical control.

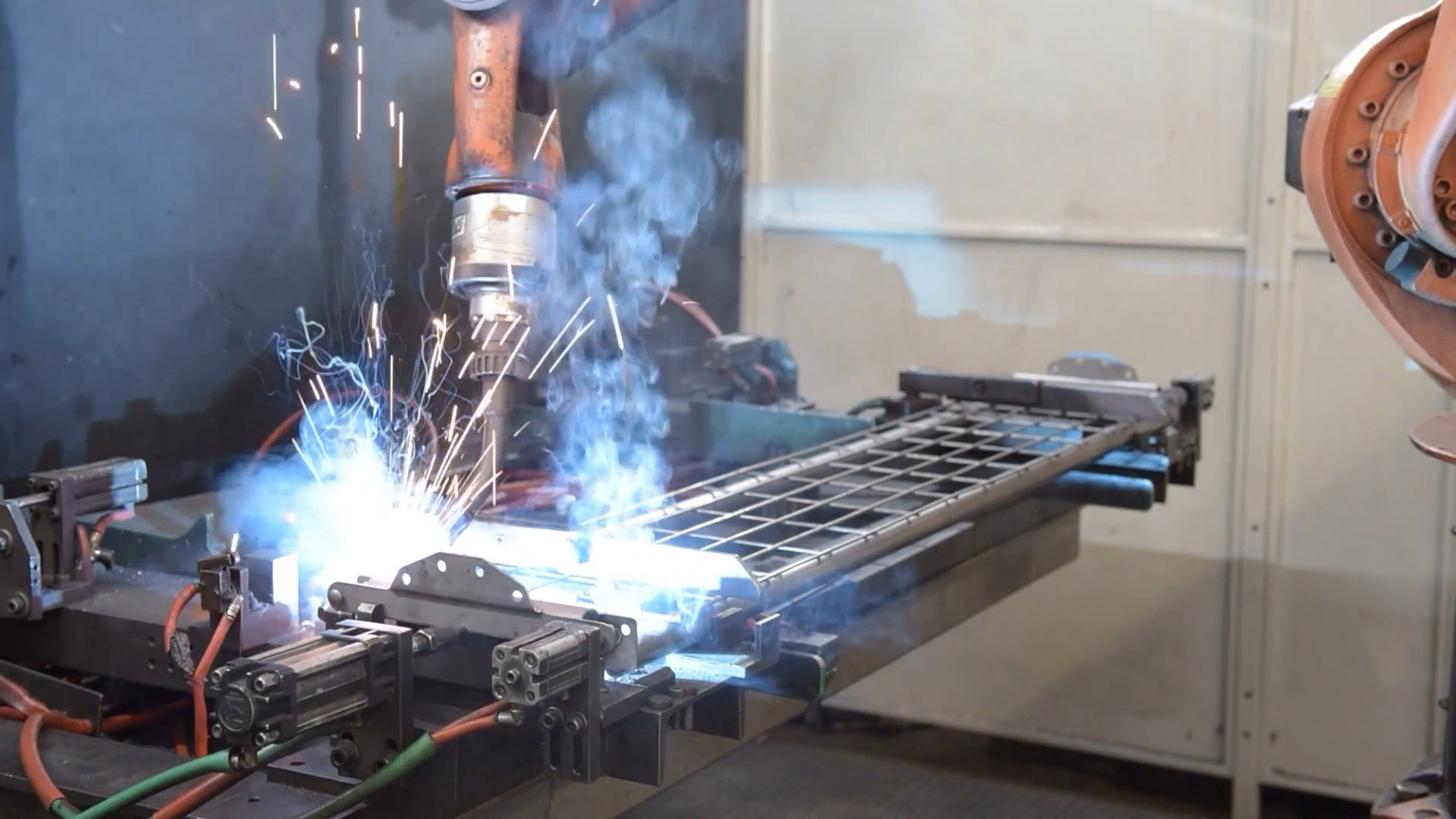

Welding: The welding

is performed in an automated way, using sophisticated robots which perform

great precision welds.

Phosphorous-degreasing:

In the phosphorous-degreasing tunnels, the hot water is sprayed at high

pressure on all networks and mechanisms. With this process the industrial

grease is eliminated, in the way to guarantee uniform In the

phosphorous-degreasing tunnels, the hot water is sprayed at high pressure on

all networks and mechanisms. With this process the industrial grease is

eliminated, in the way to guarantee uniform painting without imperfections.

Painting: The lacquering system is fully automated: dispensers of electrostatic powder paint move from top to bottom at the passage of each single piece to ensure an uniform coating on all parts.

Deliveries: The company

does directly the majority of deliveries with own trucks and specialized

personnel. For foreign deliveries it uses external couriers.